So, your pressure vessels all have proper CRN registration, you say? Do the vessel flanges properly allow for connected piping loadings? Do allowable vessel loads match connected piping required loads? You might be very surprised to find if your vessel drawings show no allowable flange connection loadings whatsoever.

If the flange loadings on CRN registered vessel drawings are less than what the connecting piping system requires, then the CRN registrations for those vessels are invalid. Operating improperly registered pressure vessels would obviously be illegal, and would not be where you want to be.

CRN Challenges

Unfortunately for plant owners, project managers, and especially for pressure piping system engineers, timelines do push for pressure vessels to be purchased with CRN registration well before pressure piping system connection loadings are precisely determined. So required flange loadings often cannot be precisely specified before vessel manufacture.

Vessel CRN registrations are normally issued by regulators well in advance of considering the pressure piping to which the vessels are to be connected.

Pressure piping system registrations are normally issued by regulators without detailed consideration of connection loads, or of whether the connecting vessel CRN registrations allow for connection loading or not. All pressure piping systems are to be authenticated by a professional engineer, who takes full responsibility for all aspects of a pressure piping system design.

Design Challenges

Pressure piping system engineers can properly approve a design that requires connection loads less than or equal to what connecting vessels allow. There are several potential approaches for this, including:

- the connecting vessels need CRN alterations that include the required connection loads,

- new CRN(s) is/are needed,

- the pressure piping design needs connection loads reduced below those allowed by the vessels, and / or

- the vessel(s) and piping need to be altered so that the allowed and required connection loads can align.

If connecting piping imparts any loads to a pressure vessel, then those loads need to be included on the CRN registered design drawing, if the CRN registration is to be valid for that vessel.

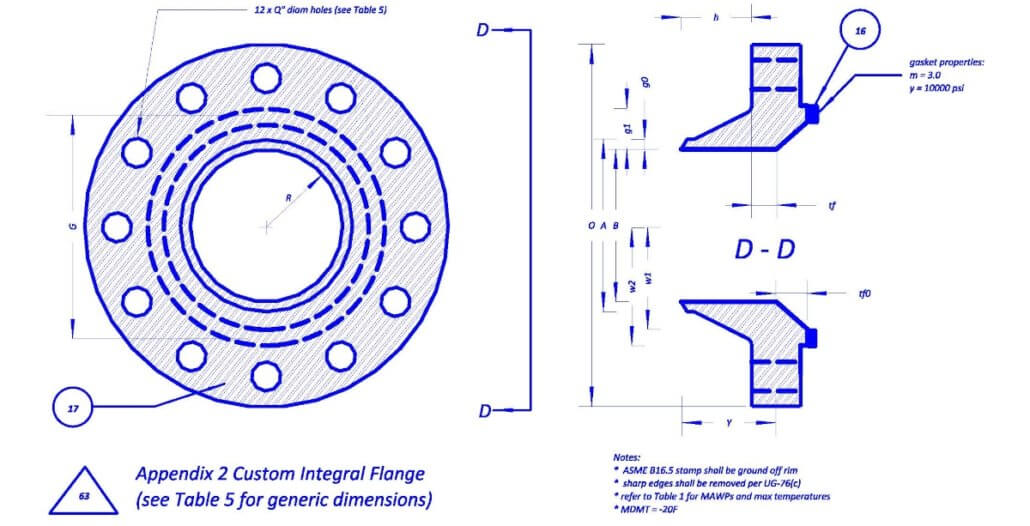

Flanges need not have a separate CRN registration, and can instead be registered as part of a vessel subject to adequate justification, using the quality program of the vessel manufacturer, per CSA B51 clause 4.2.1.

Alternatively, flanges can be registered separately with a CRN apart from the vessel manufacturer. Flange CRN registration (equipment with a CRN of 0B******.** or similar) does not include consideration of external loadings. There are two basic routes for the CRN registration of steel flanges with a gasket inside the bolt circle: i) ASME B16.5 / B16.47 for standard flanges, or ii) with ASME Section VIII-1 Appendix 2 for custom flanges. ASME B16.5 / B16.47 provides empirically determined pressure and temperature limits for standard flanges, and Appendix 2 provides calculation based rules for custom flange design justification. These minimum requirements must be met, notwithstanding whatever proof testing, FEA analysis, UG-22 loadings, or any ASME Section VIII-1 paragraph U-2(g) considerations that may exist. For example, an FEA or even a proof test cannot properly justify the CRN registration and construction of a gusseted flange, or a flange that doesn’t otherwise meet ASME B16.5 / B16.47 or ASME Section VIII-1 Appendix 2 mandatory requirements.

Maximum allowed vessel flange loadings if any, need to be specified on vessel CRN drawings, in terms of three forces and three moments in rectilinear coordinate directions.

Work is reportedly ongoing by ASME to document how to best ensure no flange leakage, even when loading is present, with an expanded method to calculate required bolt torque and the suitability of various types of gaskets further to ASME Section VIII-1 paragraph UG-44, and further to mandatory ASME Section VIII-1 Appendix 2. Revisions to ASME Section VIII-1 paragraph UG-44 are expected with the next edition of ASME Section VIII-1, hopefully sometime in 2023.

Plan a CRN Audit Focused on Flanges

To help ensure your pressure vessels are properly CRN registered and designed with respect to their flange connections, consider following these steps:

- Audit all your pressure vessel CRN registration documentation, noting:

- allowed nozzle loadings;

- vessel design conditions;

- all nozzle dimensions and materials;

- shell and head dimensions;

- gasket properties and bolt torques;

- materials;

- name of vessel manufacturer; and

- design calculations.

- Audit the connecting pressure piping system, noting:

- required flange connection loads per authenticated piping system design documentation; and

- identify those responsible for the design.

- Compare the required loads (see 2 above) with allowed loads (see 1 above). If required loads exceed allowed loads, then with those responsible for the pressure piping design:

- obtain an explanation about why flange connection audits were not performed previously;

- obtain an explanation about why required pressure piping system loads exceed allowable vessel nozzle loads;

- notify the regulator and propose how the mismatch will be properly remedied for compliance, to their satisfaction; and

- work towards aligning allowed loads with required loads with a redesign of the pressure piping system configuration, with an alteration or redesign of the pressure vessel nozzle assemblies, or with a combination of both redesign and alteration.

Summary

At the outset of a project, vessel manufacturers and owners might well conservatively agree on what vessel flange loadings are allowed before vessels are specified and purchased, and well before pressure piping systems are procured and designed. Project managers and pressure piping system engineers might well thank you for this. You might even thank yourself. If design challenges down the road can be avoided, then do so as soon as possible.