7 Advantages of Informative CAMMAR CRN Registration Training

Training is Fun, Necessary, and Important A few weeks ago CAMMAR Corporation had the pleasure and privilege of presenting a customized CRN registration training seminar

Training is Fun, Necessary, and Important A few weeks ago CAMMAR Corporation had the pleasure and privilege of presenting a customized CRN registration training seminar

Waste heat boilers needing CRN registration can be hidden. When most people think of boilers needing CRN registration, they picture something really obvious. Like a

The biggest CRN number cost might surprise you. Marketing and operation delays, your internal discussions about CRN requirements, and your mistakes about what CRN number

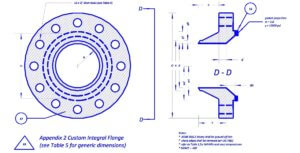

So, your pressure vessels all have proper CRN registration, you say? Do the vessel flanges properly allow for connected piping loadings? Do allowable vessel loads

Several issues routinely arise with improperly proposed non-disclosure agreements (NDA’s) pursuant to CRN registration. What follows is not legal advice, and describes some CRN issues

The Top CRN Registration Changes following notes enlarge upon CAMMAR’s article from February of this year about CRN regulatory requirements, and can be appended to

As we all embark on 2022, there are several noteworthy topics to consider as you navigate the CRN regulatory landscape, pursuant to acquiring CRN number

In Fitting CRN Registrations, any fitting that is part of a pressure piping system or attached to a pressure vessel or boiler, usually requires CRN registration,

CRN harmonization vs CRN reconciliation. Are they different? Reconciliation has been touted as an improvement to the CRN registration process. But is it simply a

The truth is, fewer CRNs are better in many ways. With fewer CRNs, it’s easier to keep track of CRN registration numbers, it’s easier

Cammar Corporation is the combination of engineering experiences extending back to 1989. It’s Director, Cameron Sterling, MSc, PEng, worked on staff at ABSA, the CRN regulatory authority in Alberta, as a Safety Codes Officer evaluating CRN designs. The company has a solid foundation based on honesty, service, unyielding perseverance of quality and safety, proficient regulatory and technical expertise, thoroughness and practical experience. Cammar is licensed to practise professional engineering in Alberta, & Ontario.