Maximum allowable working pressure (MAWP) is not the same as deisgn pressure. In order to get a CRN without going into the loop of despair, make sure that you don’t mix them up! Often people mistakenly think that MAWP can be greater than the design pressure at any location in a vessel with a single internal chamber, and they are incorrect. This article will eplain why MAWP is never greater than the design pressure.

Pressure is of utmost importance when designing wall thicknesses of pressure equipment (vessels, heat exchangers, boilers, fittings, appurtenances, pressure piping systems, thermal liquid heating systems, and so on). Obviously, thicker walls will withstand more pressure than thinner walls.

When it comes to what pressure is, the meaning of different terms is important, otherwise misunderstandings can occur and public risk can increase. Regulators certainly do not necessarily equate MAWP with design pressure, and for good reason. For starters, the MAWP of pressure equipment is never greater than design pressure (in the absence of a separated internal chamber), even though there are those in industry that would argue otherwise. Designs showing an MAWP greater than design pressure do not warrant CRN registration since they contradict code requirements, and they indicate a misunderstanding of the difference between the two.

MAWP vs Design Pressure

Per mandatory Appendix 3-2 of ASME Section VIII-1, MAWP is “the maximum gage pressure permissible at the top of a completed vessel in its normal operating position at the designated coincident temperature for that pressure. This pressure is the least of the values for the internal or external pressure to be determined by the rules of this Division for any of the pressure boundary parts, including static head…”

In contrast, design pressure is “the pressure used in the design of a vessel component together with the coincident design metal temperature, for the purpose of determining the minimum permissible thickness or physical characteristics of the different zones of the vessel. When applicable, static head shall be added to the design pressure to determine the thickness of any specific zone of the vessel (see UG-21).”

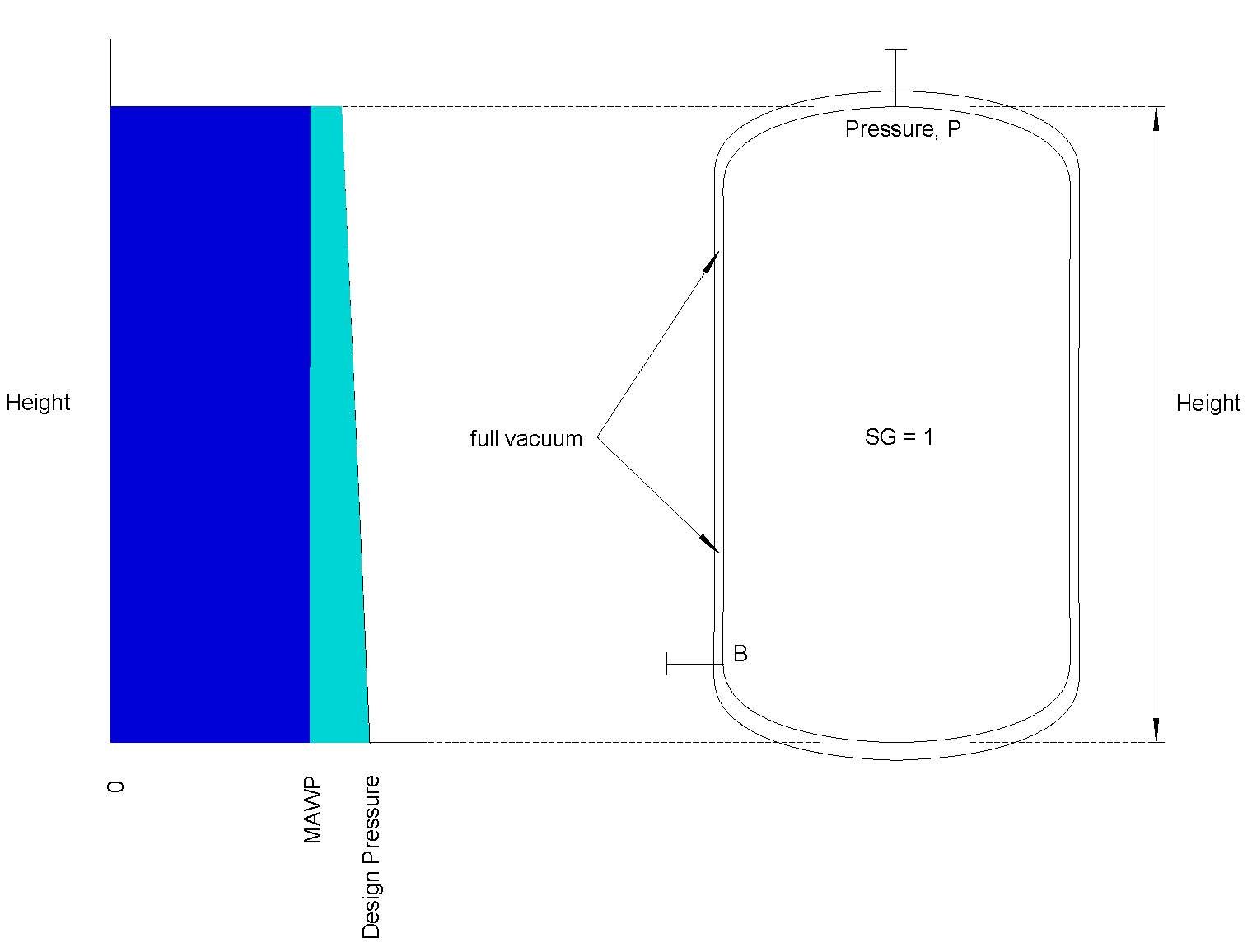

I’ve included a diagram to illustrate the point with an example. Dark blue is MAWP. Dark blue + light blue = design pressure. In this instance, design pressure includes the addition of a vacuum jacket and static pressure, like what you might see with a cryogenic vessel containing liquid nitrogen or oxygen.

As you can see, MAWP is never more than design pressure (in the absence of a separated internal chamber).

Just a few more points to make…Some software these days will take the design pressure input and then, with assistance of some iterative techniques, suggest a maximized pressure which is greater than the design requirements and call it MAWP. This is contrary to code requirements, promotes the wrong idea of what MAWP is and leads to incorrect understanding. But software is never supposed to be wrong! Well, think again, since design pressure is never less than MAWP.

Also, process facility piping designs might well use terms similar to design pressure or MAWP to describe the maximum process pressure. Sometimes, this pressure might be transcribed onto the mechanical equipment list or specification sheet by mistake! But beware, maximum process pressure, MAWP, and vessel design pressure are certainly not always the same, and cannot necessarily be interchanged.

And, for small fittings not subject to significant static head or vacuum, the MAWP is in some cases the same as design pressure and, for such fittings, MAWP and design pressure are thereby often used interchangeably on fitting drawings.

To summarize:

- MAWP is never more than design pressure (in the absence of a separated internal chamber);

- MAWP is the maximum internal pressure at the top of the pressure equipment;

- Design pressure is dependent on location in the pressure vessel; and

- MAWP and design pressure are significantly different.